Modular (container) slaughter is a relatively new product on the US market. To date, the slaughter was carried out or

on a well-equipped production lines, facilities or tiled (at best) room with a desk and a bucket to collect the blood and viscera. The virtual absence of the professional equipment for slaughter on farms are not allowed to fully realize the potential of farms to obtain high-quality market product.

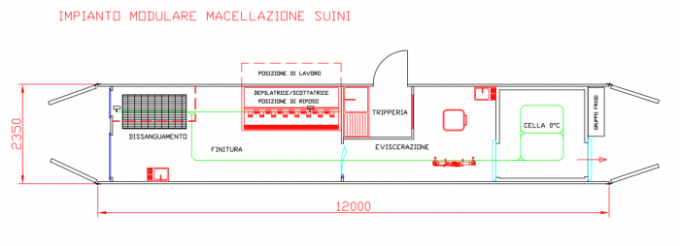

Portable container slaughter is a complete production line, equipped with all necessary equipment and appliances. In the container is installed all the necessary equipment according to production technology. The clever layout of the shop, high manufacturability and ease of use of equipment allows for a minimum number of staff while receiving an output of high-quality meat.

Application of technology:

The electronic stunner has a positive impact on the quality and flavor characteristics of meat. Electroshock design of the device is so simple that does not require a high level of training. Most importantly, it does not cause stress, which allows beginners to quickly master the farmer a new niche of deep processing.Manual transfer line, located over the entire working area simplifies the process of transporting a carcass from operation to operation, saving time. When ordering a portable slaughterhouse additional hardware may be chosen. This hardware will be installed during the production of slaughterhouse.

Unlike stationary slaughterhouses, portable slaughterhouse comes fully assembled and ready to use form. You only need to connect the electricity, water and sewer. After this, the slaughterhouse is ready to produce.

Mobile portable plants are best suited to organizations small and medium-sized industrial enterprises in the food industry and have many advantages over traditional capital construction:

• construction of plant and installation of equipment carried out at the factory shops in the warm, rather than on a construction site in captivity by the weather and "unforeseen circumstances";

• finish and hygiene company was originally located at a high level;

• losses during transportation and installation are minimized;

• timetable for the project is much more reliable and there are no construction delays. Therefore, capital is linked to a short time before the start of production - investors will appreciate this;

• modular construction also makes it possible to later move the enterprise, for example, to a new location in case of changes in terms of the lease area, the expediency of doing business in a given region, and to counter administrative pressure;

• possibility of the shop, along with the walls and support systems provides lease financing to the entire complex, not just the equipment.

The SINT Technology for the past 6 years has created a new frontier of agro-food processing, designing container fully equipped and accessories for the various stages of agro-processing.

Here are some types of plants MODULAR PORTABLE slaughterhouse in 20' or 40' containers.

Here are some types of plants MODULAR PORTABLE slaughterhouse in 20' or 40' containers.